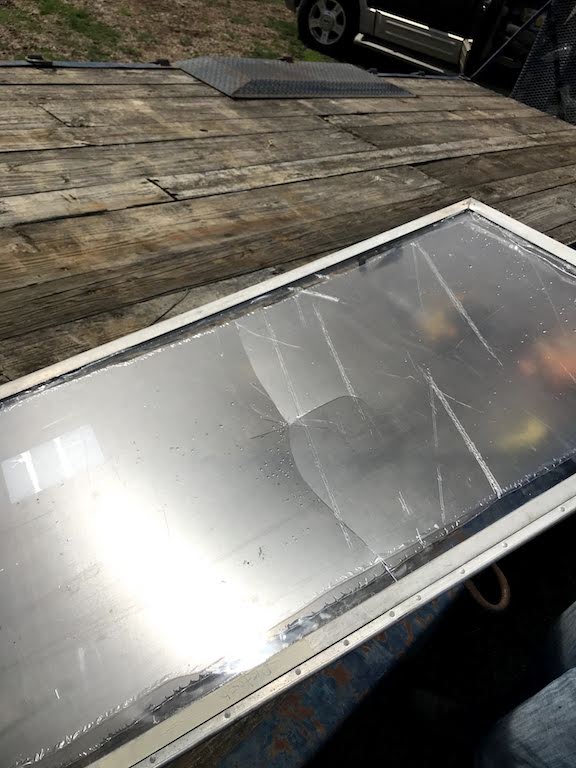

When we bought the Airstream, you could not miss the crack down the front window. There was no easy repair for this very large crack. We knew right off the bat that this would need to be fully replaced.

Brandon removed the window from the airstream and pulled out the broken glass. He first brought it to a glass store to see if they could replace it. We ordered the tempered glass for it, wanting the strength of it. That same night, Brandon researched what others do to replace broken windows. People recommended using a material called Lexan, which was significantly cheaper than the glass. Brandon was on board with that and picked up the window frame the next day from the glass store.

After purchasing the Lexan, Brandon drilled out the rivets on the front of the window frame. They were a pain because there are little bars that slide inside of the frame channel. The rivets go through the frame, through the bar, and then exit the back of the frame. They bent way too easily. Anyway, once the rivets were out from some maneuvering, the frame was split apart into the four sides. Whoever the genius was that tried to fix the window leak before us thought jamming it full of caulk and silicone would do the trick. Not so much. It was a pain to clean all the crap out of the track. Once these things were removed, the sheet of Lexan was cut to the exact size of the previous glass. So the Lexan wouldn’t crack or scratch, we taped the line we were going to cut and used a jigsaw with a fine toothed metal blade for a cleaner cut.

Once the Lexan was ready, we filled the frame with fresh silicone, inserted the Lexan, and carefully placed each side of the frame together, being cautious about making sure that the bars in the frame channel were placed correctly.

The window was all set and ready to be installed. Unfortunately, the window was left outside one night and we had some rough wind. The Lexan cracked, right down the middle. Bummer. It needed to be replaced… again. This time, Brandon had an even better idea.

Instead of using Lexan again, Brandon took the window frame to a local hardware store where they cut us out a sheet of plexiglass instead. This was A LOT thicker than the Lexan material and would have way more strength. After hours of removing the previous silicone that had attached the Lexan to the window frame, we were able to re-silicone the new plexiglass into the frame. After a few days of drying and another layer of silicone, it was set. This time, we would NOT be leaving it out in the wind to blow around. We were so excited that this part was done because we were able to reattach the window and no longer tarp the whole front end of the trailer.

The side window… now that wasn’t as easy.

From the beginning, we knew the entire side window would need replaced. Luckily, the frame was kept by the previous owner, which was a huge life AND money saver. Whole windows from the Airstream community cost a fortune! Brandon bought Lexan to also use on this window. Since this was a side window and much smaller than the front window, we had high hopes that this would work well. Brandon and Dave were concerned about the curve of the airstream, and therefore, the curve of the window.

Brandon and Dave worked together to cut the Lexan to fit the frame. The boys used the frame as a stencil, pretty simple. But they budgeted for extra space around each edge so that there would be Lexan to grab in the frame with silicone. They used a jigsaw with a metal, fine tooth blade to cut out the Lexan. Then, they siliconed the Lexan inside the frame. We let it sit for a few days after that to solidify.

Once dried, we put the window up onto the trailer. Brandon felt it was important to mention here about how to reattach the windows. At the top of the windows is a hinge in which the top track of the window frame sits in. To reattach, you need to position this at just the right angle. Act as if you are opening the window way higher that you usually would, matching the openings and slowly aligning the hinge to the frame.

Another problem arose here. We chose the Lexan because it was flexible. However, what we didn’t predict was that it would still not be able to conform to the curves of our airstream. So, our next step in the coming weeks is to heat the Lexan with a heat gun in order to bend and mold to the shape of the curves. Hopefully this will allow it to lay nicely and fully seal up the window.

Much love,

Lauren

Recent Comments